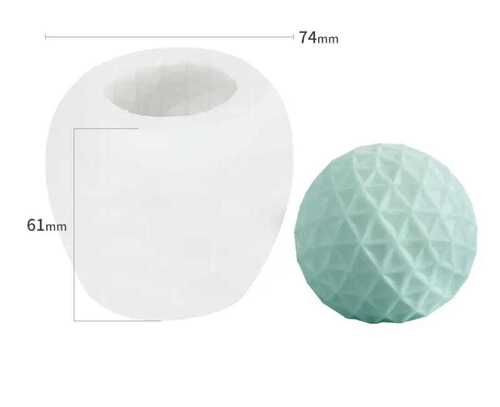

Ball Shape Candle Moulds

Price 299 INR/ Piece

Ball Shape Candle Moulds Specification

- Tolerance

- 0.05 mm

- Life Span

- 50,000+ cycles

- Mould Base

- Stainless Steel

- Core Material

- Aluminium

- Working Process

- Precision Casting

- Material

- Food Grade Silicone & Metal

- Shaping Mode

- Injection Mould

- Punch Dies

- High Strength Steel

- Die Head

- Interchangeable Ball Shaped Die Head

- Easy Cleaning

- Dishwasher Safe

- Heat Resistance

- Up to 250°C

- Usage

- Candle Making, DIY Craft

- Ball Size

- Available in 3 cm, 5 cm, 7 cm diameter options

- Customizability

- Sizes and shapes upon request

- Cavity Count

- Multi-cavity (6 balls per mould)

- Surface Finish

- Polished, Non-stick Interior

- Demoulding Type

- Manual/Push-to-Release

- Colour

- Silver/Transparent

Ball Shape Candle Moulds Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Nhava SHeva

- Payment Terms

- Paypal, Cash Advance (CA), Cash in Advance (CID), Western Union

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Ball Shape Candle Moulds

Made of high-quality silicone, durable andreusable, non-stick surface and flexible, could come out clear shape.Itis made of high-quality silica gel.

Our silicone moulds are designed with smoothinside, reducing the steps of polishing finished products.

You just need to wait the resin in the mould isfully solidified, then twist your silicone mould and release your finishedproduct from your moulds.

You can make exquisite handicrafts with them,develop your imagination to create personalized crafts as meaningful gifts foryour lover, friends, family or your customers on Christmas, Mother's Day,Valentine's Day parties, home decoration and other occasions.

You could use them for Epoxy Resin, Soap, Candle, LotionBar, Bath Bomb, Beeswax, Polymer Clay, Plaster of Paris, Cement, Concrete andother art crafts making. It is also great for making ice, chocolates, candy,jelly, cake decoration, dessert etc.

This reusable resin casting mould is a good choicefor you to share your handicraft with your friends and family, enjoy your happytimes together.

Note: Please store the silicone mould at roomtemperature to avoid direct sunlight and dust.

Please do not approach open flames or heat sources,and don't scrub with steel wire.

Wash and dry in time after use.

Precision Multi-Cavity Design

Utilize six-ball cavities per mould to efficiently create uniform candles in one pour. Each cavity is meticulously crafted with a 0.05 mm tolerance, ensuring consistent shapes and sizes for every candle you produce.

Premium Materials and Longevity

Constructed from food grade silicone, stainless steel base, and aluminium core, this mould delivers uncompromising durability. With a lifespan exceeding 50,000 cycles and resistance to high temperatures, you gain a reliable tool for professional and creative use.

Flexible Demoulding and Maintenance

Enjoy the manual push-to-release function for easy candle removal and a non-stick polished finish for hassle-free cleaning. The dishwasher-safe feature promotes swift maintenance, making it suitable for busy candle studios or hobbyists.

Customizable for Your Needs

Choose from three available ball sizes or request custom shapes and diameters to match your creative vision. Interchangeable ball-shaped die heads and high strength steel punch dies ensure tailored production for dealers and fabricators alike.

FAQ's of Ball Shape Candle Moulds:

Q: How do I use the Ball Shape Candle Mould for crafting candles?

A: Simply prepare your candle material, pour it into the non-stick cavities, and allow it to cool. Once set, manually push to release each ball candle easily, thanks to the mould's precision casting and push-to-release design.Q: What materials are used for these moulds and why?

A: The mould features food grade silicone, a stainless steel base, and an aluminium core, ensuring safety, durability, and stability against high heat. High strength steel punch dies and interchangeable ball die heads further support longevity and precision.Q: When should I consider ordering custom sizes or shapes for the candle mould?

A: You can request custom sizes or shapes whenever your project demands unique candles. The manufacturer offers tailor-made options, making these moulds ideal for artisans, retailers, and service providers requiring specific designs.Q: Where can these ball shape candle moulds be sourced in India?

A: They're available through dealers, fabricators, manufacturers, suppliers, producers, traders, wholesalers, and retailers across India, offering flexible purchasing channels for both small and bulk orders.Q: What is the process behind the mould's high precision and durability?

A: Each mould is produced via precision casting and injection moulding techniques, ensuring exact tolerances, smooth finishes, and robust construction for professional-grade candle making and extended life span.Q: How do I clean and maintain the mould for optimal performance?

A: Thanks to its non-stick polished surface and dishwasher-safe design, it's easy to clean after each use. Regular washing and proper storage will help preserve its finish and functionality for up to 50,000+ cycles.Q: What benefits do these multi-cavity candle moulds offer to manufacturers and DIY users?

A: They streamline production, provide consistent results, minimize waste, and withstand frequent usage. Customizability, easy demoulding, and reliable heat resistance make them suitable for both industrial and creative applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

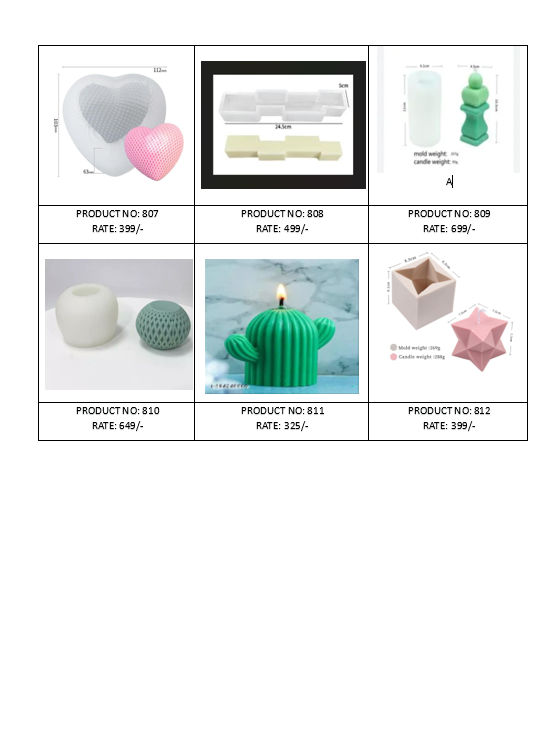

More Products in Candle Moulds Category

Man Shape Candle Moulds (01)

Price 299 INR / Piece

Minimum Order Quantity : 1 Piece

Core Material : Silicone Rubber

Die Head : Precision Machined

Material : Other, Food Grade Silicone

Working Process : Other, Injection Moulding

House Shape Candle Moulds

Price 299 INR / Piece

Minimum Order Quantity : 1 Piece

Core Material : Highgrade SS

Die Head : Single cavity

Material : Other, Metal alloy

Working Process : Other, Precision Casting

Succulent Silicone Candle Moulds

Price 299 INR / Piece

Minimum Order Quantity : 1 Piece

Core Material : Premium foodgrade silicone

Die Head : Precise single cavity

Material : Other, 100% silicone, BPAfree

Working Process : Other, Liquid silicone injection moulding

Rose Candle Moulds

Price 299 INR / Piece

Minimum Order Quantity : 1 Piece

Core Material : Aluminium

Die Head : Single Head

Material : Other, Aluminium

Working Process : Other, Gravity Casting

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry