Hugging Bear Shape Candle Moulds

Hugging Bear Shape Candle Moulds Specification

- Working Process

- Injection Molding

- Tolerance

- 0.1 mm

- Life Span

- 5000-8000 Uses

- Core Material

- Silicone

- Mould Base

- Metal Alloy

- Material

- Food-Grade Silicone

- Shaping Mode

- Customized Mould

- Punch Dies

- Standard

- Die Head

- Single

- Cleaning

- Hand Washable and Dishwasher Safe

- Usage

- Candle Making, Soap Making, Resin Crafts

- Temperature Resistance

- -40°C to 220°C

- Mould Finish

- Smooth Non-Stick Surface

- Color

- Translucent White

- Weight

- Approx 120 g

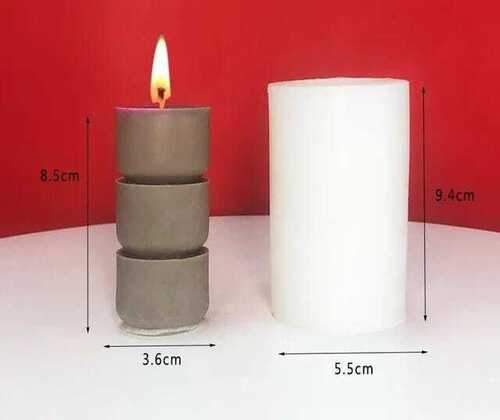

- Dimensions

- Approx 8.5 cm x 7 cm x 4.5 cm

- Demoulding

- Easy Demould Design

- Cavity Type

- Single

- Shape

- Hugging Bear

- Suitable Wax Types

- Soy Wax, Paraffin, Beeswax

Hugging Bear Shape Candle Moulds Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Nhava Sheva

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Domestic Market

- All India

About Hugging Bear Shape Candle Moulds

Made of high-quality silicone, durable andreusable, non-stick surface and flexible, could come out clear shape.Itis made of high-quality silica gel.

Our silicone moulds are designed with smoothinside, reducing the steps of polishing finished products.

You just need to wait the resin in the mould isfully solidified, then twist your silicone mould and release your finishedproduct from your moulds.

You can make exquisite handicrafts with them,develop your imagination to create personalized crafts as meaningful gifts foryour lover, friends, family or your customers on Christmas, Mother's Day,Valentine's Day parties, home decoration and other occasions.

You could use them for Epoxy Resin, Soap, Candle, LotionBar, Bath Bomb, Beeswax, Polymer Clay, Plaster of Paris, Cement, Concrete andother art crafts making. It is also great for making ice, chocolates, candy,jelly, cake decoration, dessert etc.

This reusable resin casting mould is a good choicefor you to share your handicraft with your friends and family, enjoy your happytimes together.

Note: Please store the silicone mould at roomtemperature to avoid direct sunlight and dust.

Please do not approach open flames or heat sources,and don't scrub with steel wire.

Wash and dry in time after use.

Superior Material and Longevity

Made from premium food-grade silicone with a metal alloy base, the Hugging Bear Shape Candle Mould promises safe handling and lasting performance. Designed to withstand repeated use, its lifespan ranges between 5,000 and 8,000 cycles, delivering consistent results for every project. The non-stick finish ensures swift release and simple cleaning after each use.

Versatile Creative Applications

This mould excels in various craft practices beyond candle making-it is perfect for soap production and resin art, thanks to its robust construction and smooth finish. Compatible with soy wax, beeswax, and paraffin, the gently translucent Hugging Bear shape brings a playful charm to crafts while accommodating diverse mediums.

Effortless Cleaning and Maintenance

Keeping your mould in top condition is simple, whether you prefer hand washing or using a dishwasher. Its temperature resistance from -40C to 220C means thermal stresses won't degrade the material, and the easy demould design makes it convenient for everyday projects, reducing downtime and optimizing workflow.

FAQ's of Hugging Bear Shape Candle Moulds:

Q: How do I use the Hugging Bear Shape Candle Mould for candle making?

A: Begin by melting your preferred wax (soy, paraffin, or beeswax) and pour it into the mould's single cavity. Allow it to cool and set at room temperature or in a refrigerator. Once cured, the non-stick surface and easy demoulding design enable you to release the finished candle effortlessly.Q: What types of materials can be used with this mould?

A: You can employ a range of materials, including soy wax, paraffin, beeswax, soap bases, and resin. The high-quality silicone supports various craft projects and produces finely detailed hugging bear shapes across these different mediums.Q: When should I clean the mould after use, and how?

A: It's recommended to clean the mould immediately after use, especially when working with wax or resin. The mould is hand washable and dishwasher safe, so you can either rinse it in warm, soapy water or place it in the dishwasher for thorough cleaning without risk of degrading the surface.Q: Where can this mould type be sourced in India?

A: The Hugging Bear Shape Candle Mould is available through various dealers, manufacturers, fabricators, producers, retailers, service providers, suppliers, traders, and wholesalers in India. Many online and offline craft supply outlets also stock it for creative enthusiasts and businesses.Q: What is the benefit of the smooth non-stick surface and easy demoulding?

A: The smooth non-stick surface prevents sticking and ensures your candles, soaps, or resin crafts retain crisp details. The easy demoulding design reduces the risk of damage during release, saves time, and maximizes production efficiency for both hobbyists and professionals.Q: How does the injection-molded construction enhance the mould's performance?

A: Injection molding provides precision shaping, resulting in a dimensionally accurate and robust mould with reliable tolerance (0.1 mm). This method guarantees consistency across multiple uses, supporting high-quality results whether you are manufacturing at scale or crafting at home.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

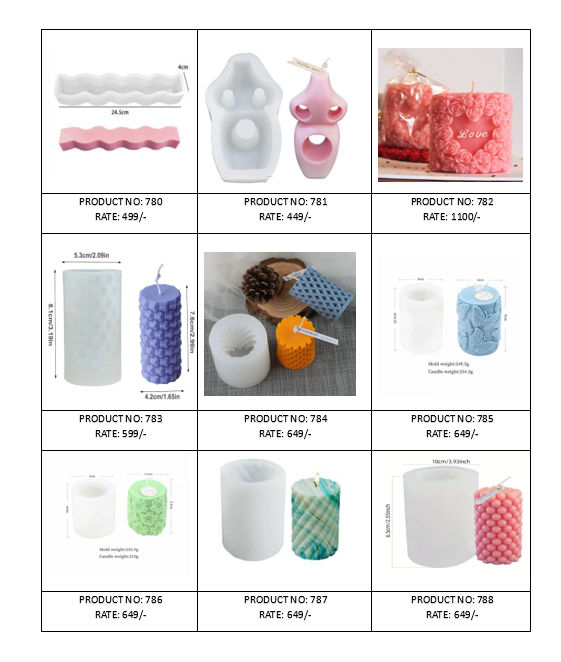

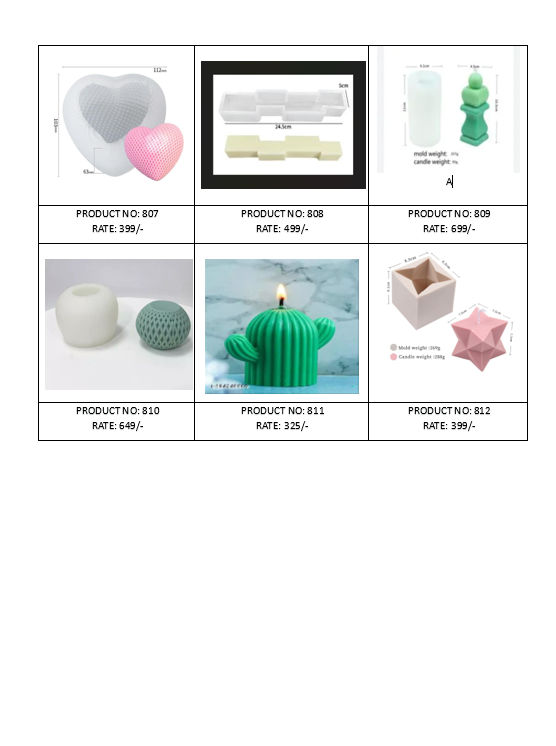

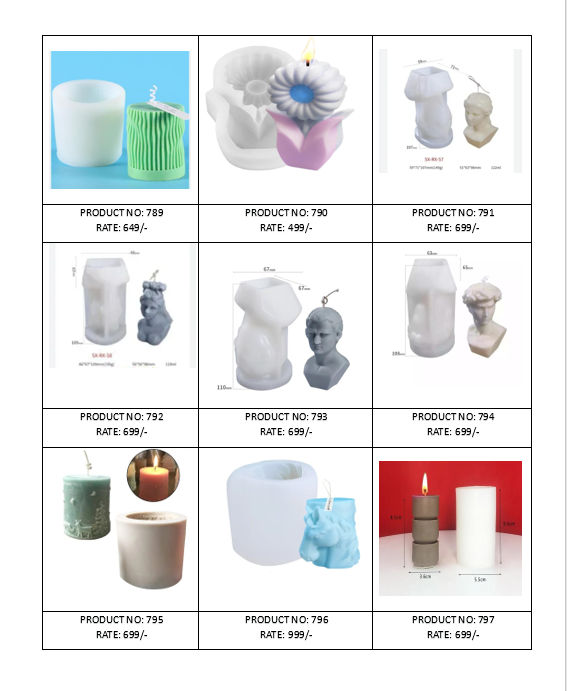

More Products in Candle Moulds Category

3D Cylinder Candle Moulds

Price 299 INR / Piece

Minimum Order Quantity : 1 Piece

Shaping Mode : Other, 3D Cylinder

Life Span : Over 1000 cycles

Die Head : Standard Cylinder

Core Material : Silicone

Horse Shape Candle Moulds

Price 299 INR / Piece

Minimum Order Quantity : 1 Piece

Shaping Mode : Other, Casting

Life Span : Up to 10,000 cycles

Die Head : Removable

Core Material : Stainless Steel

Rose Shape with Love Candle Moulds

Price 299 INR / Piece

Minimum Order Quantity : 1 Piece

Shaping Mode : Other, Mould

Life Span : 5000+ uses

Die Head : Rose & LOVE Letter Shape

Core Material : Silicone

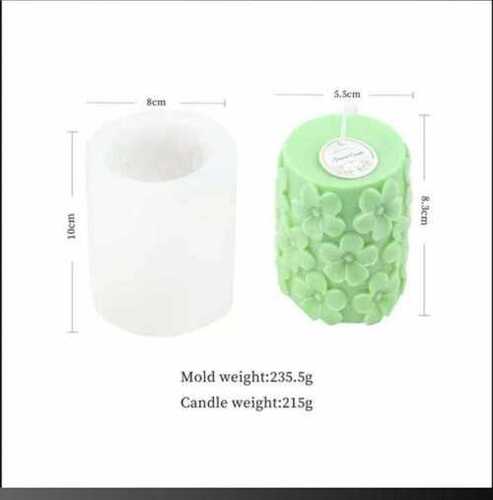

Can Shape Candle Moulds (Flower)

Price 299 INR / Piece

Minimum Order Quantity : 1 Piece

Shaping Mode : Other, Injection Moulding

Life Span : Up to 10000 uses

Die Head : Interchangeable, reinforced

Core Material : Stainless Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry