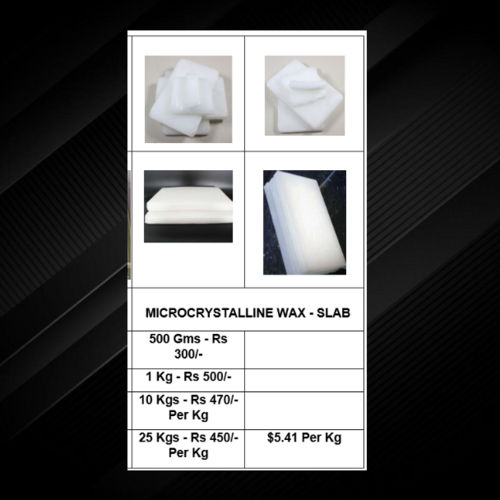

MICROCRYSTALLINE WAX - SLAB

Price 500 INR/ Kilograms

MICROCRYSTALLINE WAX - SLAB Specification

- Solubility

- Insoluble in water, soluble in oils and organic solvents

- Appearance

- Translucent to white solid slab

- Extraction Type

- Refined extraction

- Raw Material

- Petroleum Derived

- Odour

- Odourless or very slight waxy odor

- Purity

- 98% - 100%

- CAS No

- 63231-60-7

- Volume

- 25 Kg (per slab)

- Storage

- Ambient, dry location

- Density

- 0.94 Gram per cubic centimeter(g/cm3)

- Gender

- Unisex

- Product Type

- Microcrystalline Wax - Slab

- Ingredients

- Fully Refined Microcrystalline Wax

- Age Group

- All ages (Industrial use)

- Feature

- High plasticity; flexible; high melting point

- Shelf Life

- 2 Years

- Storage Instructions

- Store in a cool, dry place away from direct sunlight

- Congealing Point

- 68°C - 75°C

- Form

- Solid Slab

- Penetration (at 25°C)

- 15 - 35 dmm

- Usage/Application

- Cosmetics, candles, rubber, packaging, adhesives

- Melting Point

- 65°C - 75°C

- Colour

- White to off-white

- Flash Point

- >250°C

- Oil Content

- Less than 3.0%

- Packaging Type

- Plastic-wrapped slabs, 25 kg net

- Toxicity

- Non-Toxic

MICROCRYSTALLINE WAX - SLAB Trade Information

- Minimum Order Quantity

- 1 Kilograms

- FOB Port

- Nhava Sheva

- Payment Terms

- Paypal, Cash Advance (CA), Cash in Advance (CID), Western Union

- Supply Ability

- 500 Kilograms Per Day

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- MSDS, Certificate of Analysis & Lab Report

About MICROCRYSTALLINE WAX - SLAB

Microcrystalline wax is a type of wax produced by DE-oiling petrolatum, as part of the petroleum refining process. It is characterized by the fineness of its crystals in contrast to the larger crystal of paraffin wax. It consists of high molecular weight saturated aliphatic hydrocarbons. Microcrystalline wax is generally darker, more viscous, denser, tackier and more elastic than paraffin waxes, and has a higher molecular weight and melting point. The elastic and adhesive characteristics of microcrystalline waxes are related to the non-straight chain components which they contain. The typical microcrystalline wax crystal structure is small and thin, making them more flexible than paraffin wax.

Uses for Microcrystalline Wax in titles:

1) Base for chewing gum, lipstick, cold creams, and ointments (where they harden, lubricate, carry additives, and protect against moisture)

2) Food packaging, moisture proofing, film, foil, and corrugated board

3) Increasing the fluidity and the flexible bonding of hot-melt adhesives

4) Crayons, candles and caulk to sealants and fine polishes

5) Host for compounds that prevent rust

6) Insulating materials

7) Candle Additives

Reliable Thermal Stability

This microcrystalline wax provides a flash point above 250C, ensuring safety in high-temperature applications and offering dependable stability. Its congealing and melting points (68C-75C and 65C-75C, respectively) meet a wide range of industry needs, from cosmetics to industrial manufacturing.

Versatile Industrial Uses

Ideal for producers, manufacturers, traders, and wholesalers in India, this wax is widely utilized in cosmetics, candles, rubber, packaging, and adhesives. Its high plasticity and flexibility make it adaptable for multiple applications, supporting consistent quality across finished goods.

Safe, Odourless, and Long-lasting

Formulated from fully refined ingredients, this non-toxic, odourless (or slight waxy odor) slab is safe for use in environments involving all age groups, specifically for industrial purposes. Its shelf life of up to 2 years assures lasting effectiveness when stored properly.

FAQ's of MICROCRYSTALLINE WAX - SLAB:

Q: How should microcrystalline wax - slab be stored for optimal shelf life?

A: To maximize shelf life, store the wax slabs in a cool, dry place away from direct sunlight. This preserves quality for up to 2 years.Q: What applications are suitable for this microcrystalline wax?

A: This wax is ideal for cosmetics, candle-making, adhesives, rubber goods, and packaging due to its high plasticity and adaptability.Q: What are the main benefits of using microcrystalline wax compared to other waxes?

A: Microcrystalline wax provides excellent flexibility, a higher melting point, low oil content, and is highly pure, making it advantageous for products requiring stability and plasticity.Q: Can this wax be used in food packaging or with direct skin contact?

A: While non-toxic and suitable for cosmetics, its intended use is for industrial purposes. For food-contact applications, check specific regulatory compliance standards.Q: What is the proper method to process microcrystalline wax into finished products?

A: Melt the wax at temperatures between 65C and 75C and blend with other compatible oils or solvents as needed for your formulation before molding or further processing.Q: Is this wax safe for all age groups and environments?

A: Yes, being non-toxic and odourless, it is safe for industrial applications involving products for all age groups but should be used as specified.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

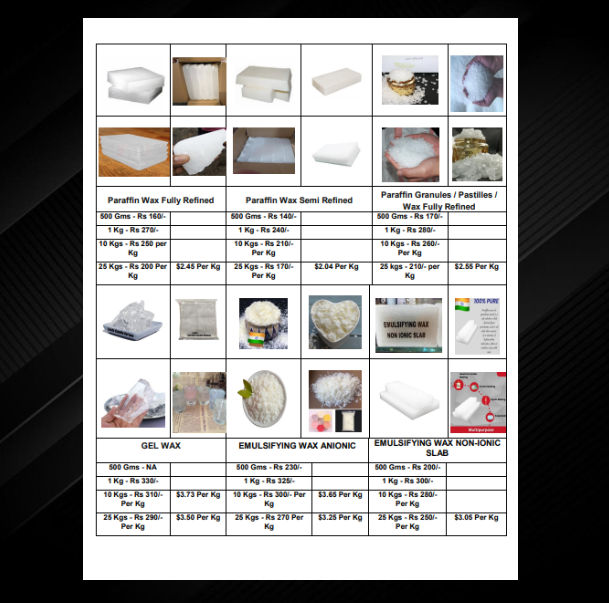

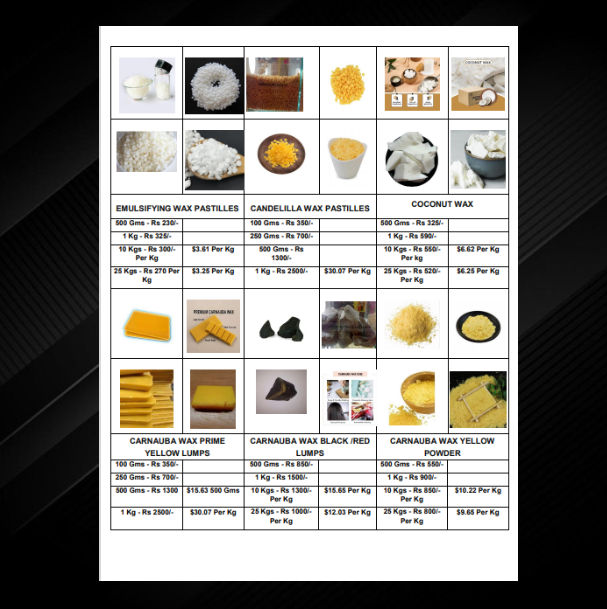

More Products in Cosmetic Waxes Category

EMULSIFYING WAX PASTILLES

Price 325 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Odour : Odourless

CAS No : 67762270

Age Group : Adults

Purity : 99% Min

CANDELILLA WAX PASTILLES

Price 2500 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Odour : Characteristic

CAS No : 8006448

Age Group : Other, All Age Group

Purity : 100%

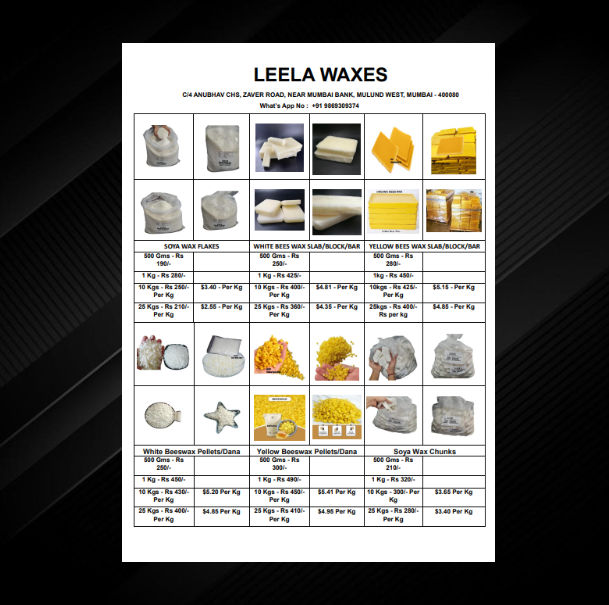

YELLOW BEESWAX PELLETS/DANA

Price 490 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Odour : Mild, natural honey aroma

CAS No : 8012893

Age Group : Other, All ages

Purity : 99.8% Minimum

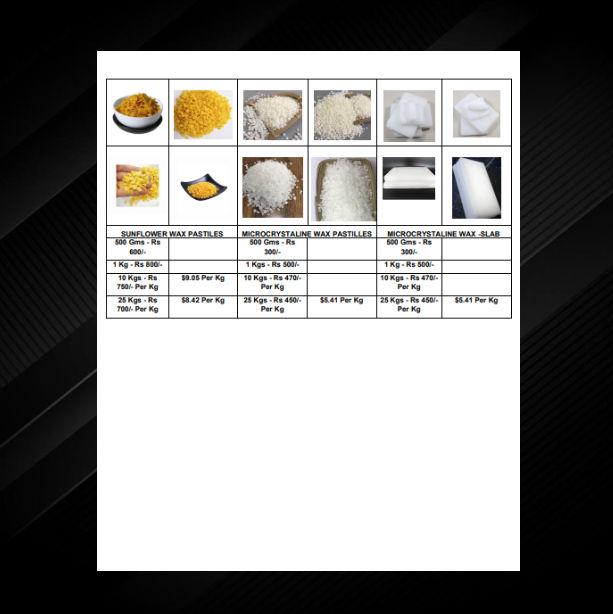

SUNFLOWER WAX PASTILLES

Price 800 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Odour : Mild, natural

CAS No : 8001216

Age Group : Adults

Purity : 99%

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry