Oval Shape Soap Moulds

Price 599 INR/ Piece

Oval Shape Soap Moulds Specification

- Mould Base

- High-grade Aluminum Alloy

- Tolerance

- 0.02 mm

- Core Material

- Hardened Stainless Steel

- Working Process

- Precision CNC Machined

- Life Span

- Up to 100,000 cycles

- Material

- Aluminum Alloy + Stainless Steel

- Shaping Mode

- Compression Moulding

- Punch Dies

- Interchangeable Steel Dies

- Die Head

- Custom Oval Die Head

- Mould Size

- Custom as per requirement

- Use For

- Handmade Cold Processed Soap, Glycerin Soap, Bath Bombs

- Demoulding

- Flexible, Easy Release

- Soap Shape

- Oval

- Cavity Number

- Multiple (Customizable)

- Operating Temperature

- -40°C to 230°C

- Mould Color

- Transparent / Color Customizable

- Surface Finish

- Mirror Polished

Oval Shape Soap Moulds Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Nhava Sheva

- Payment Terms

- Paypal, Cash Advance (CA), Cash in Advance (CID), Western Union

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Oval Shape Soap Moulds

Made of high-quality silicone, durable andreusable, non-stick surface and flexible, could come out clear shape. Itis made of high-quality silica gel.

Our silicone moulds are designed with smoothinside, reducing the steps of polishing finished products.

You just need to wait the resin in the mould isfully solidified, then twist your silicone mould and release your finishedproduct from your moulds.

You can make exquisite handicrafts with them,develop your imagination to create personalized crafts as meaningful gifts foryour lover, friends, family or your customers on Christmas, Mothers Day,Valentines Day parties, home decoration and other occasions.

You could use them for Epoxy Resin, Soap, Candle, LotionBar, Bath Bomb, Beeswax, Polymer Clay, Plaster of Paris, Cement, Concrete andother art crafts making. It is also great for making ice, chocolates, candy,jelly, cake decoration, dessert etc.

This reusable resin casting mould is a good choicefor you to share your handicraft with your friends and family, enjoy your happytimes together.

Note: Please store the silicone mould at roomtemperature to avoid direct sunlight and dust.

Please do not approach open flames or heat sources,and dont scrub with steel wire.

Wash and dry in time after use.

Customizable for Every Need

Tailor your soap production with moulds available in fully customizable sizes, cavity numbers, and even colors. Whether you require small batches or industrial-scale output, our moulds adapt seamlessly to your requirements and branding, ensuring the perfect fit for your handmade soap or bath bomb creations.

Engineered for Reliability and Longevity

Constructed from premium aluminum alloy and hardened stainless steel, these moulds offer extreme durability and resistance to wear. Precision CNC machining provides consistent tolerances while the mirror-polished finish ensures easy release and minimal maintenance. Achieve up to 100,000 cycles per mould, maximizing the value of your investment.

Optimal User Experience

Enjoy efficient demoulding with our flexible, easy-release design, reducing waste and saving time with every batch. The moulds high thermal tolerance makes them ideal for a broad temperature range, accommodating a variety of soap making processes. Transparent and customizable colors further help in monitoring and branding your artisan soap batches.

FAQs of Oval Shape Soap Moulds:

Q: How do I choose the correct cavity number and size for my soap moulds?

A: You can specify the number of cavities and the mould size during the ordering process. This allows you to tailor the mould exactly to your production volume and individual soap bar dimensions, ensuring efficiency and minimal material loss.Q: What are the benefits of a mirror-polished mould surface?

A: A mirror-polished surface ensures a smooth, flawless release of soap and bath bombs, minimizing sticking and reducing the need for post-production finishing. This feature helps save both time and effort in your workflow.Q: When should I use these moulds for cold processed or glycerin soap?

A: Our moulds are optimized for both handmade cold processed and glycerin soaps, thanks to their broad temperature tolerance and non-stick properties. They can be used at any stage of your soap production where custom shapes and consistent results are needed.Q: Where are these moulds manufactured and can they be shipped across India?

A: The oval shape soap moulds are manufactured using precision CNC machining in India and can be supplied by dealers, fabricators, manufacturers, and wholesalers. We offer nationwide shipping through our extensive supplier and trader network.Q: What is the process for using and demoulding soap from these moulds?

A: Simply pour your blended soap mixture into the mould cavities, allow it to set at the appropriate temperature, and flex the mould for easy and clean release. The flexible design and mirror-polish provide swift removal without damaging delicate shapes.Q: What advantages do high-grade aluminum alloy and hardened stainless steel provide?

A: Using high-grade aluminum alloy for the mould body ensures lightweight, corrosion resistance, and fast cooling, while the hardened stainless steel core maintains precise shaping and longevity, supporting up to 100,000 use cycles with minimal wear.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Soap Moulds Category

Mandala Design Soap Moulds (2)

Price 400 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Nontoxic silicone

Die Head : Precision cut for intricate mandala patterns

Mould Base : Sturdy silicone base

Tolerance : 0.5 mm

Flower and Leaf Design in Round Shape Soap Moulds

Price 450 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Food Grade Silicone

Die Head : Single Cavity Die Head

Mould Base : Premium Grade Aluminium Alloy

Tolerance : 0.01 mm

Rose Print in Oval Shape Soap Moulds

Price 350 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Nontoxic, BPAfree Silicone

Die Head : Precision Engineered for Detailed Rose Pattern

Mould Base : Highgrade Aluminum Alloy

Tolerance : 0.02 mm

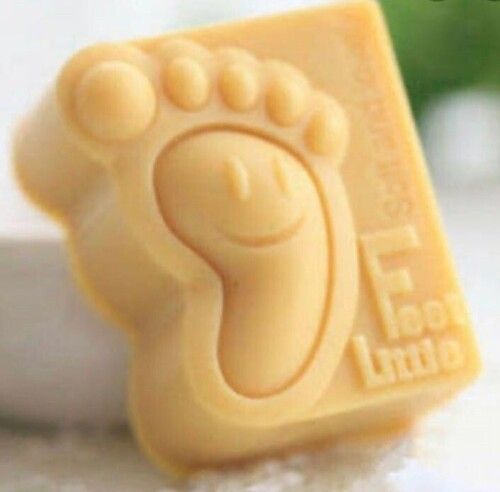

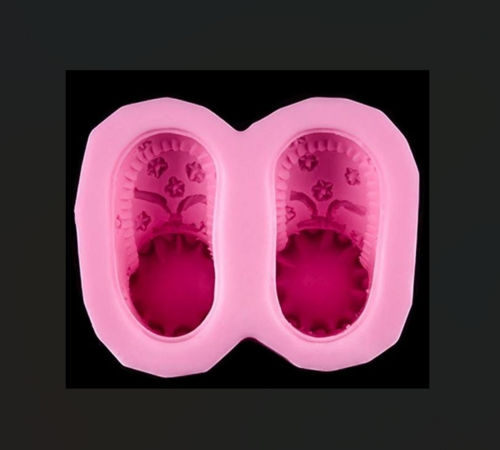

Baby Foot Shape Soap Moulds

Price 400 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Food Grade Silicone

Die Head : Single Cavity

Mould Base : Plastic

Tolerance : 0.1 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry