Rectangle Shape Moulds

Price 299 INR/ Piece

Rectangle Shape Moulds Specification

- Mould Base

- Steel

- Tolerance

- 0.01 mm

- Life Span

- Up to 100,000 cycles

- Working Process

- Injection Moulding

- Core Material

- Hardened Steel

- Material

- Aluminium / Steel

- Shaping Mode

- Plastic Injection Mould

- Punch Dies

- High Precision

- Die Head

- Customizable

- Runner Type

- Cold/Hot Runner

- Hardness

- HRC 48-52

- Design Software

- AutoCAD/SolidWorks Used

- Colour

- Silver/Grey

- Surface Finish

- Polished

- Dimension

- Customizable as per requirement

- Processing Technology

- CNC Machining, EDM

- Cavity Number

- Single or Multiple

- Usage

- Industrial Moulding Applications

- Shape

- Rectangle

- Portability

- Portable/Fixed

- Cleaning Method

- Manual/Chemical Cleaning Compatible

Rectangle Shape Moulds Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Nhava Sheva

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Rectangle Shape Moulds

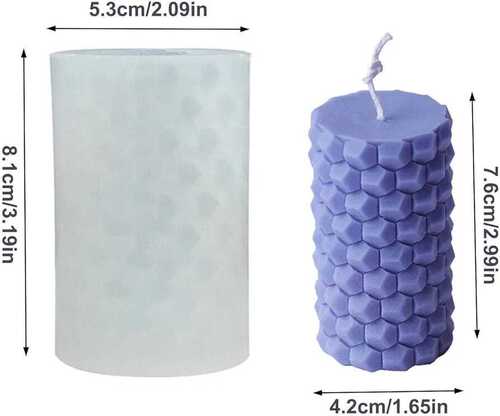

Made of high-quality silicone, durable and reusable, non-stick surface and flexible, could come out clear shape. It is made of high-quality silica gel.

Our silicone moulds are designed with smooth inside, reducing the steps of polishing finished products.

You just need to wait the resin in the mould is fully solidified, then twist your silicone mould and release your finished product from your moulds.

You can make exquisite handicrafts with them, develop your imagination to create personalized crafts as meaningful gifts for your lover, friends, family or your customers on Christmas, Mother's Day, Valentine's Day parties, home decoration and other occasions.

You could use them for Epoxy Resin, Soap, Candle, Lotion Bar, Bath Bomb, Beeswax, Polymer Clay, Plaster of Paris, Cement, Concrete and other art crafts making. It is also great for making ice, chocolates, candy, jelly, cake decoration, dessert etc.

This reusable resin casting mould is a good choice for you to share your handicraft with your friends and family, enjoy your happy times together.

Note: Please store the silicone mould at room temperature to avoid direct sunlight and dust.

Please do not approach open flames or heat sources, and don't scrub with steel wire.

Wash and dry in time after use.

Customizable Rectangle Moulds for Versatile Applications

Our rectangle shape moulds are adaptable to a wide range of industrial applications, thanks to customizable dimensions, cavity numbers, and die heads. Whether you operate as a dealer, manufacturer, or fabricator in India, these moulds can be tailored to your precise requirements.

High-Precision Engineering and Longevity

Manufactured using advanced CNC machining and EDM technologies, each mould guarantees high dimensional accuracy (with tolerances up to 0.01 mm) and a robust lifespan, supporting up to 100,000 injection moulding cycles. The use of hardened steel and aluminium ensures consistent, reliable performance.

Easy Maintenance and Cleaning Compatibility

These moulds are suitable for both manual and chemical cleaning procedures, making upkeep simple and efficient. Their polished surface finish and steel base resist wear and facilitate straightforward maintenance, extending usability.

FAQ's of Rectangle Shape Moulds:

Q: How are the dimensions of the rectangle shape moulds customized?

A: The rectangle shape moulds can be customized according to your specific requirements by adjusting dimensions, cavity number, and die head design. Our team uses AutoCAD and SolidWorks software during the design phase, ensuring precise customization that aligns with your application needs.Q: What materials are used in the construction of these moulds?

A: We use high-grade hardened steel or aluminium for the core and mould base, ensuring excellent durability and performance. The choice of material depends on the desired hardness, lifecycle, and application requirements of your project.Q: Where can these moulds be used?

A: These moulds are suitable for a wide range of industrial moulding applications across manufacturing, fabrication, retail, and service sectors in India. They are commonly used for producing high-precision plastic components via the injection moulding process.Q: What is the cleaning process for these rectangle moulds?

A: Our rectangle moulds support both manual and chemical cleaning methods. Regular cleaning helps maintain the polished surface finish and sustains the mould's high cycle life. Detailed cleaning instructions are provided to ensure proper maintenance and longevity.Q: How does the runner type affect the moulding process?

A: These moulds are compatible with both cold and hot runner systems. The choice of runner type impacts cycle time, material usage, and efficiency in your injection moulding process. We can recommend the best option based on your production volume and application.Q: When should I consider replacing the mould?

A: Each mould is designed to withstand up to 100,000 cycles under proper use and maintenance. It is recommended to monitor performance regularly and consider replacement or refurbishment once you approach the mould's expected lifespan or notice signs of wear affecting product quality.Q: What are the benefits of using these CNC-machined rectangle moulds?

A: Benefits include high dimensional accuracy, repeatability, and smooth surface finish. Advanced CNC machining and EDM technologies ensure that even complex geometries are produced with reliable consistency, enhancing productivity and reducing rejection rates.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

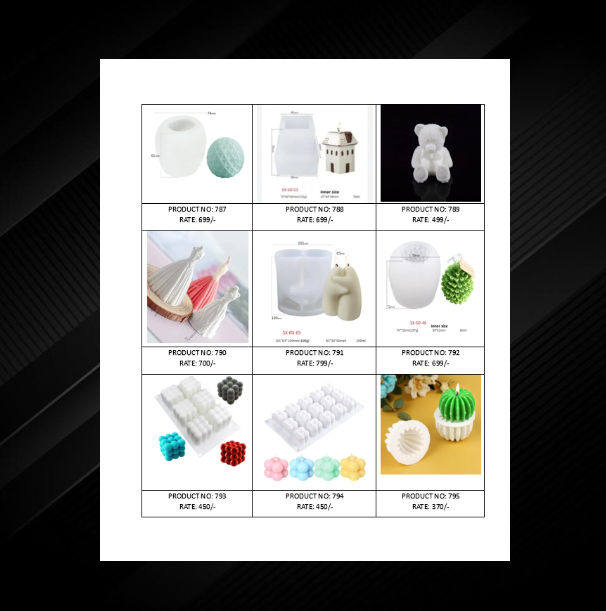

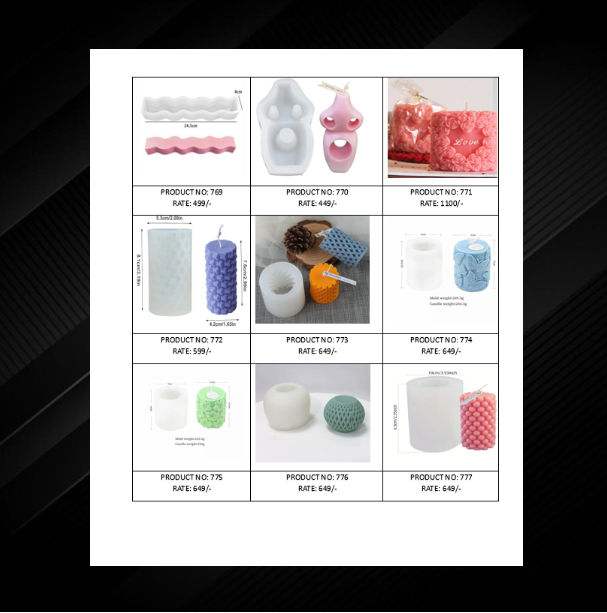

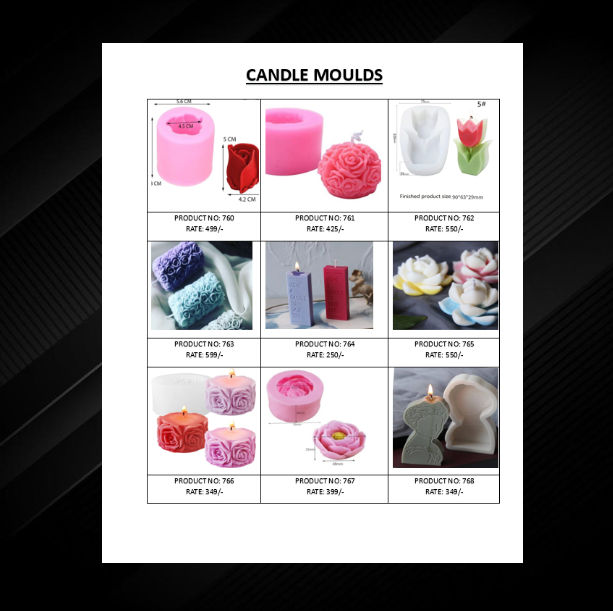

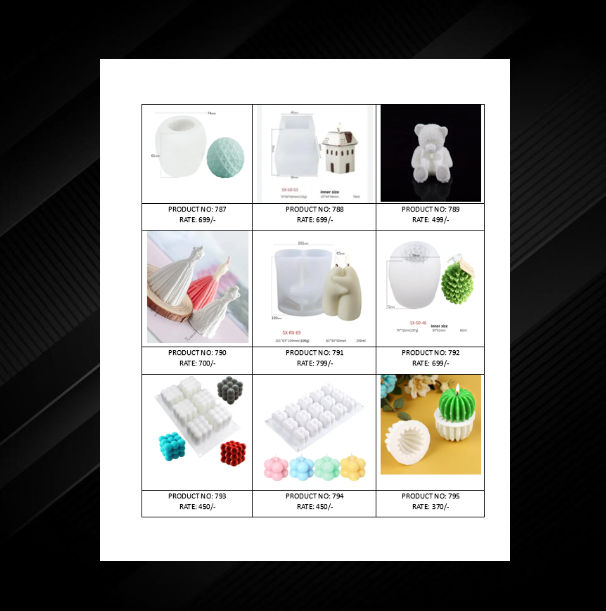

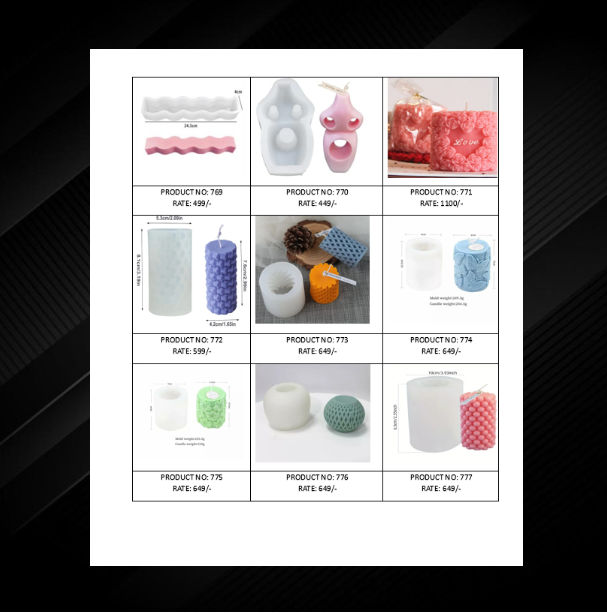

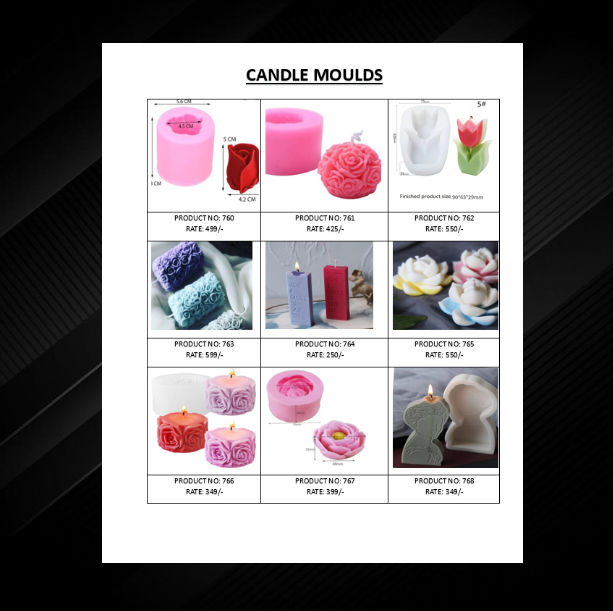

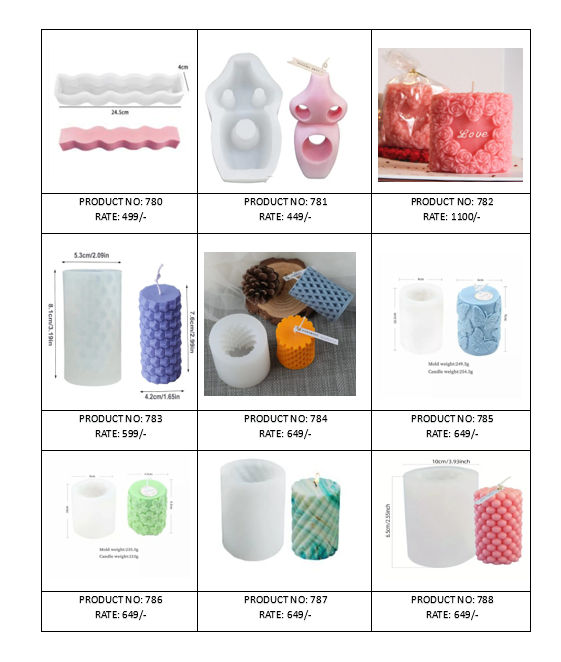

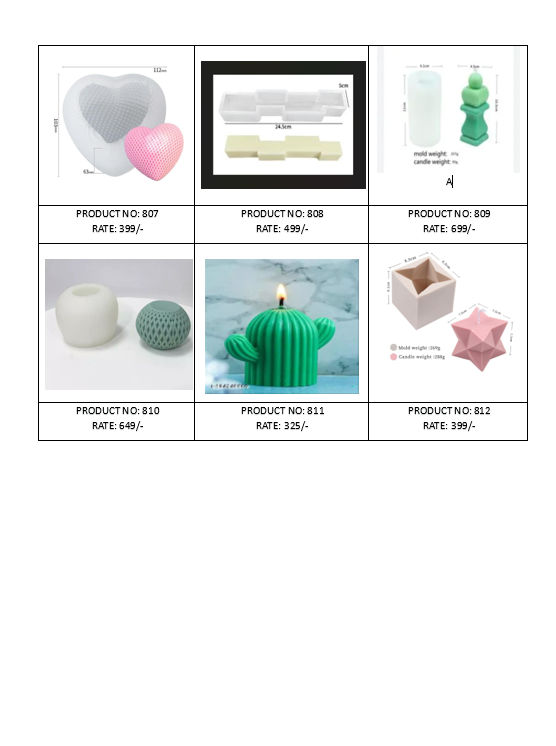

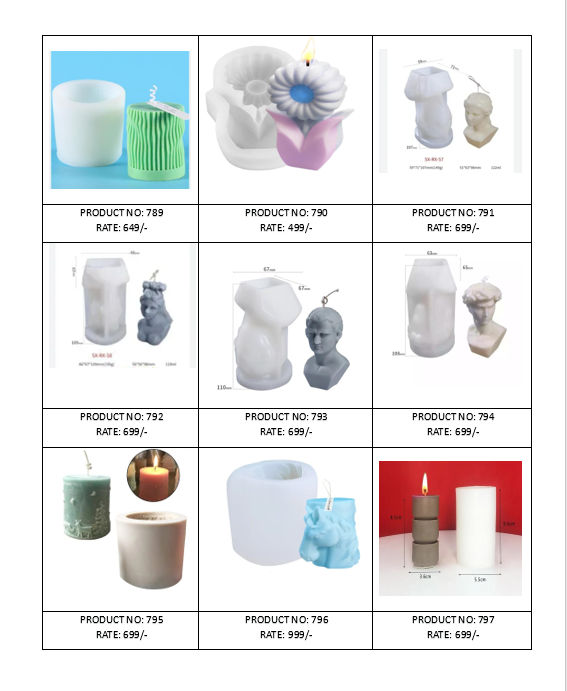

More Products in Candle Moulds Category

Woman Shape Candle Moulds (02)

Price 299 INR / Piece

Minimum Order Quantity : 1 Piece

Shaping Mode : Silicone Mould

Mould Base : Plastic

Die Head : Single Cavity

Punch Dies : Precision Cut

Horse Shape Candle Moulds

Price 299 INR / Piece

Minimum Order Quantity : 1 Piece

Shaping Mode : Other, Casting

Mould Base : HighGrade Aluminium

Die Head : Removable

Punch Dies : Custom Designed for Horse Shape

Can Shape Candle Moulds (Round Stones)

Price 299 INR / Piece

Minimum Order Quantity : 1 Piece

Shaping Mode : Other, Can Shaped with Round Stones Pattern

Mould Base : Highgrade Aluminum Alloy

Die Head : CNC Machined, Polished Finish

Punch Dies : Included, Custom Fit

Can Shape Candle Moulds (Pyramid)

Price 299 INR / Piece

Minimum Order Quantity : 1 Piece

Shaping Mode : Other, Injection Moulding

Mould Base : Steel Alloy

Die Head : Custom Pyramid Design

Punch Dies : Replaceable

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry