Tree Shape Candle Moulds

Tree Shape Candle Moulds Specification

- Working Process

- Precision Casting & CNC machining

- Life Span

- Over 10,000 cycles

- Tolerance

- 0.02 mm

- Mould Base

- Heavy Duty Steel

- Core Material

- High-Grade Aluminium Alloy

- Material

- Aluminium & Steel

- Shaping Mode

- Tree Shape

- Punch Dies

- Interchangeable Hardened Steel

- Die Head

- Solid Single Piece

- Color

- Silver Grey

- Candle Finish Compatibility

- Matte & Glossy

- Dimensions

- 250 mm x 180 mm x 60 mm

- Surface Treatment

- Polished & Anti-stick Coated

- Feature

- Reusable & Easy Cleaning

- Heat Resistance

- Up to 350°C

- Application

- Suitable for Paraffin, Soy and Beeswax

- Cavity Count

- 4 Cavities

- Demoulding Mechanism

- Manual or Hydraulic

- Weight

- 2.8 kg

- Usage

- Hand Craft & Industrial Candle Production

Tree Shape Candle Moulds Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Nhava Sheva

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Domestic Market

- All India

About Tree Shape Candle Moulds

Made of high-quality silicone, durable and reusable, non-stick surface and flexible, could come out clear shape. It is made of high-quality silica gel.

Our silicone moulds are designed with smooth inside, reducing the steps of polishing finished products.

You just need to wait the resin in the mould is fully solidified, then twist your silicone mould and release your finished product from your moulds.

You can make exquisite handicrafts with them, develop your imagination to create personalized crafts as meaningful gifts for your lover, friends, family or your customers on Christmas, Mother's Day, Valentine's Day parties, home decoration and other occasions.

You could use them for Epoxy Resin, Soap, Candle, Lotion Bar, Bath Bomb, Beeswax, Polymer Clay, Plaster of Paris, Cement, Concrete and other art crafts making. It is also great for making ice, chocolates, candy, jelly, cake decoration, dessert etc.

This reusable resin casting mould is a good choice for you to share your handicraft with your friends and family, enjoy your happy times together.

Note: Please store the silicone mould at room temperature to avoid direct sunlight and dust.

Please do not approach open flames or heat sources and don't scrub with steel wire.

Wash and dry in time after use.

Robust Build and Precise Craftsmanship

Manufactured using precision casting and CNC machining, this candle mould boasts a heavy-duty steel base and a high-grade aluminium alloy core. Its solid single-piece die head and interchangeable hardened steel punch dies deliver outstanding durability and dimensional accuracy, ensuring consistent results cycle after cycle.

Versatile Application and Superior Compatibility

The mould supports a variety of waxes, including paraffin, soy, and beeswax, and accommodates both industrial and handcraft production. Whether you're a retailer, wholesaler, or producer, the mould's compatibility with matte and glossy finishes offers creative flexibility-delivering tree-shaped candles with each use.

Easy Operation and Extended Service Life

Engineered for manual or hydraulic demoulding, the polished and anti-stick coated surface guarantees smooth candle removal and quick clean-up. Withstanding temperatures up to 350C and crafted to work efficiently for over 10,000 cycles, this mould ensures reliable performance and longevity for businesses across India.

FAQ's of Tree Shape Candle Moulds:

Q: How do I demould candles from the Tree Shape Candle Mould, and what is the cleaning process?

A: Candles can be removed either manually or with hydraulic assistance, thanks to the mould's polished and anti-stick coated surfaces. For cleaning, simply wash the mould with warm water and mild detergent; its easy-clean design and premium surface treatment make maintenance quick and effective.Q: What types of wax are compatible with this mould, and can I achieve both matte and glossy finishes?

A: This mould is suitable for paraffin, soy, and beeswax, supporting diverse production requirements. Its versatile design and surface treatment allow you to produce candles with either a matte or glossy finish, depending on your chosen wax and additives.Q: When should I opt for this mould in candle manufacturing and crafting enterprises?

A: Choose this mould when you need high-output, consistent tree-shaped candles with reliable quality. Its capacity for repeated use, compatibility with various waxes, and suitability for both handcraft and industrial production make it ideal for manufacturers, fabricators, retailers, and service providers.Q: Where can this mould be used, and who benefits from its features in India?

A: The mould is designed for a range of settings, from small-scale artisanal studios to large industrial candle factories. Its durability and ease of use make it beneficial for dealers, suppliers, producers, and traders operating across India.Q: What is the average lifespan of the Tree Shape Candle Mould, and how does its build contribute to longevity?

A: The mould is engineered for over 10,000 production cycles, thanks to its robust combination of a heavy-duty steel base and a high-grade aluminium alloy core. Precision machining ensures tight tolerances and exceptional endurance during intensive candle-making processes.Q: How does the precision casting and CNC machining process enhance the quality of candles produced?

A: Precision casting and CNC machining result in meticulous shaping and surface finishes. This advanced manufacturing safeguards dimensional accuracy, ensuring each candle is uniform, well-defined, and easy to demould, which minimizes defects and maximizes production efficiency.Q: What key benefits does this mould offer compared to conventional candle moulds on the market?

A: This mould stands out for its heat resistance up to 350C, reusability, easy cleaning, and extended lifespan. Its anti-stick coating, solid single-piece die head, and interchangeable punch dies collectively provide greater flexibility, durability, and ease of use compared to standard alternatives.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Candle Moulds Category

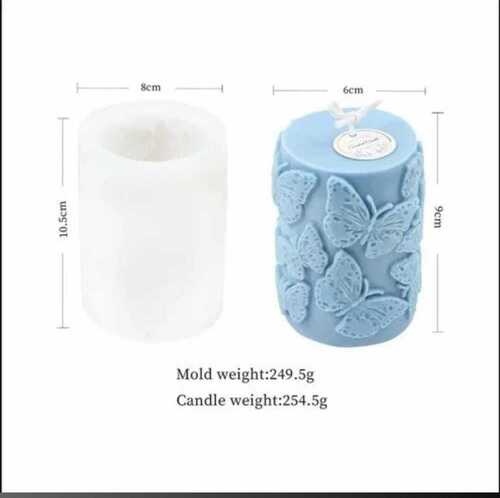

Can Shape Candle Moulds (Butterfly)

Price 299 INR / Piece

Minimum Order Quantity : 1 Piece

Tolerance : 0.05 mm

Life Span : Up to 5 years with proper care

Core Material : Highgrade Silicone

Mould Base : Aluminium

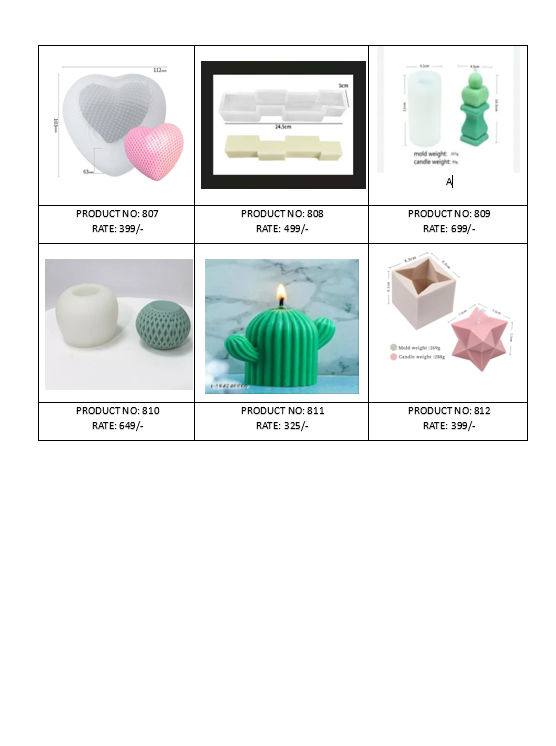

Small Cactus Shape Candle Mould

Price 299 INR / Piece

Minimum Order Quantity : 1 Piece

Tolerance : 0.02 mm

Life Span : Over 1500 cycles

Core Material : Silicone Rubber

Mould Base : Aluminum Alloy

3D Bubble Shape Candle Moulds (15 slots)

Price 299 INR / Piece

Minimum Order Quantity : 100 Pieces

Tolerance : 0.2mm

Life Span : 5000+ cycles

Core Material : Premium Silicone Rubber

Mould Base : HighDurability Silicone

Woman Shape Candle Moulds (02)

Price 299 INR / Piece

Minimum Order Quantity : 1 Piece

Tolerance : 0.2 mm

Life Span : Long Life (Varies with Usage)

Core Material : Silicone Rubber

Mould Base : Plastic

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry