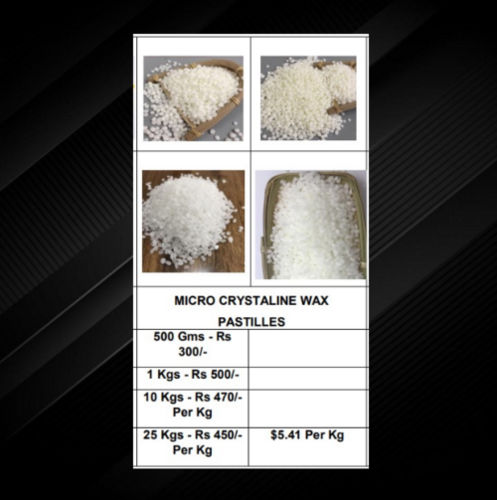

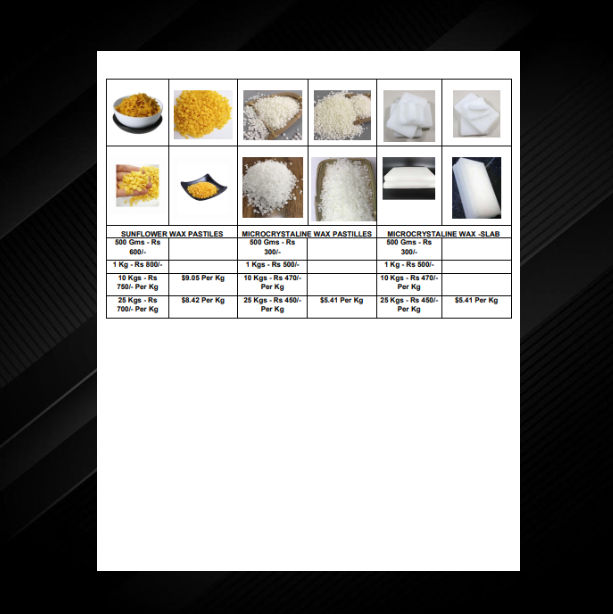

MICRO CRYSTALINE WAX PASTILLES

Price 500 INR/ Kilograms

MICRO CRYSTALINE WAX PASTILLES Specification

- Solubility

- Insoluble in water, soluble in organic solvents

- CAS No

- 63231-60-7

- Raw Material

- Petroleum

- Density

- 0.92 Gram per cubic centimeter(g/cm3)

- Odour

- Odourless or slight waxy odour

- Storage

- Ambient Temperature

- Gender

- Unisex

- Volume

- Customizable

- Purity

- 99% min.

- Extraction Type

- Refined

- Appearance

- White to off-white pastilles

- Product Type

- Micro Crystalline Wax Pastilles

- Ingredients

- Petroleum derived micro crystalline wax

- Age Group

- All ages

- Feature

- High flexibility, tackiness, and adhesive properties

- Shelf Life

- 2 Years

- Storage Instructions

- Store in a cool, dry, and well-ventilated area, away from sources of ignition

- Penetration at 25C

- 1320 dmm

- Oil Content

- 1.5% max.

- Melting Point

- 70C 80C

- Packaging

- 25 kg bags or customized

- Acid Value

- < 1 mg KOH/g

- Applications

- Cosmetics, pharmaceuticals, food additives, adhesives, candle making, rubber and tire industries

- Flash Point

- > 220C

- Congealing Point

- 68C 73C

- Ph Value

- Neutral

MICRO CRYSTALINE WAX PASTILLES Trade Information

- Minimum Order Quantity

- 1 Kilograms

- FOB Port

- Nhava Sheva

- Payment Terms

- Paypal, Cash Advance (CA), Cash in Advance (CID), Western Union

- Supply Ability

- 500 Kilograms Per Day

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- MSDS, Certificate of Analysis & Lab Report

About MICRO CRYSTALINE WAX PASTILLES

Benefits

Wax with ability to bind oils & solvents (prevent sweating of lipsticks)

Crystals insure high tensile strength and consistency (more malleable than paraffin)

Assures color uniformity in color cosmetics

Compatible with all kinds of oils & waxes

Use

Add to heated oil phase of formulas, typical use level 1 - 30% depending of product and desired viscosity. For external use only.

This wax is suited for casting and mixing with other waxes in order to change the melting temperature and plasticity.

Microcrystalline wax is a real basic wax and is used as casting wax or to mix together with other waxes. This wax can also be mixed with the

Red casting wax from our shop. The wax is flexible, thus increases the flexibility of the casting wax it is added too.

Applications

All kinds of stick cosmetics (lipstick, lip balm, concealers, deodorants), emulsions (creams, lotions), and various other cosmetics.

Versatile Industrial Applications

These micro crystalline wax pastilles find use across a spectrum of industries, including cosmetics, pharmaceuticals, food additives, adhesives, candles, and the rubber and tire sector. Their high flexibility and adhesive properties render them ideal in formulations where strong binding and soft texture are crucial. The neutral pH and high purity provide safety and compatibility in sensitive applications.

Safe and Convenient Storage

Store the wax pastilles in a cool, dry, and well-ventilated area to maintain quality and prevent hazards. As they have a flash point above 220C and are insoluble in water, it's essential to keep them away from sources of ignition. Adhering to recommended storage conditions extends shelf life and ensures performance throughout their two-year usability.

Customization and Packaging Options

To accommodate varying industrial and commercial needs, micro crystalline wax pastilles are supplied in standard 25 kg bags or tailored volumes on request. This flexibility simplifies handling and logistics for manufacturers, fabricators, and retailers across India. Custom packaging options ensure safe transport and efficient integration into production processes.

FAQ's of MICRO CRYSTALINE WAX PASTILLES:

Q: How are Micro Crystalline Wax Pastilles typically used in industry?

A: Micro Crystalline Wax Pastilles are used in a wide range of industries, including cosmetics, pharmaceuticals, food additives, adhesives, candle making, and rubber and tire manufacturing. Their high flexibility, tackiness, and adhesive properties enhance the performance of finished products, making them ideal for applications requiring strong binding and a smooth texture.Q: What is the process for incorporating micro crystalline wax into products?

A: The pastilles are usually melted at controlled temperatures (70C-80C) and blended with other ingredients to achieve the desired formulation. They dissolve in organic solvents and combine well with additives, oils, or polymers. This refined wax ensures homogeneous mixing and consistent results, especially in cosmetics and candles.Q: When is customized packaging or volume available for orders?

A: Customized packaging and volumes are available based on order requirements. Whether for large-scale manufacturing or smaller batches, suppliers in India offer flexible solutions like standard 25 kg bags or personalized packaging to suit your operational needs.Q: Where should micro crystalline wax pastilles be stored to maintain their quality?

A: Store the pastilles in a cool, dry, and well-ventilated location, away from direct sunlight and sources of ignition. Proper storage ensures product integrity, prevents contamination, and extends the wax's effective two-year shelf life.Q: What benefits do micro crystalline wax pastilles provide over other waxes?

A: Compared to other waxes, micro crystalline wax offers superior flexibility, tackiness, and adhesive properties. Thanks to its high purity and neutral pH, it's particularly suited for sensitive applications like cosmetics and pharmaceuticals, ensuring safety and compatibility.Q: How can I ensure safe handling during the usage of this wax?

A: Always melt the wax in a controlled environment, keeping temperatures within the specified range and ensuring proper ventilation. As the flash point is above 220C, avoid open flames or high heat sources nearby. Use protective equipment if necessary, especially in industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cosmetic Waxes Category

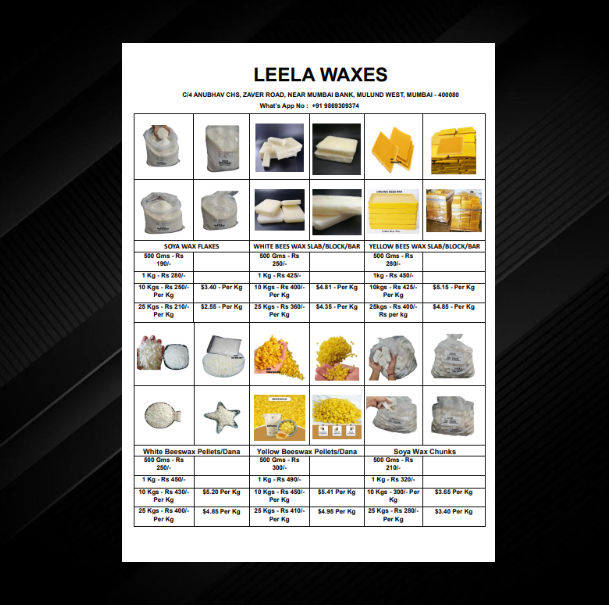

SOYA WAX CHUNKS

Price 320 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Feature : Other, Biodegradable, Nontoxic, Vegan

Extraction Type : other, Expeller Pressed

Purity : 99%

Volume : 500 Grams

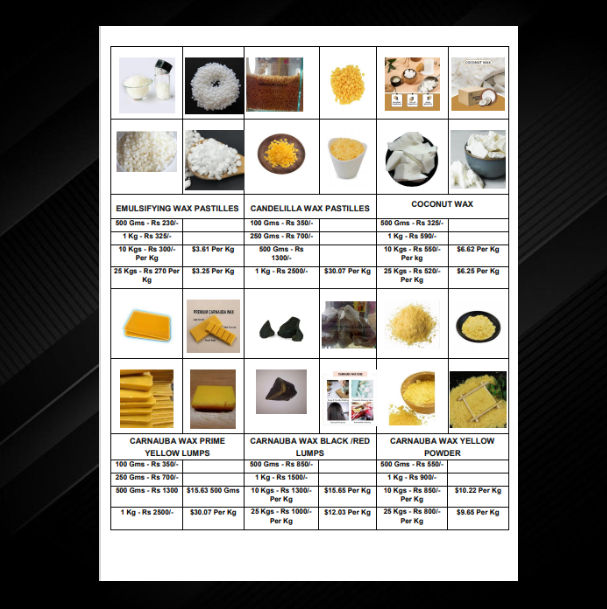

CANDELILLA WAX PASTILLES

Price 2500 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Feature : Other, Natural, Plant Derived, NonToxic

Extraction Type : other, Plant Extraction

Purity : 100%

Volume : 25 Kilograms (kg)

CARNAUBA WAX PRIME YELLOW LUMPS

Price 2500 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Feature : Other, High melting point, Nontoxic, Hard natural wax

Extraction Type : other, Mechanical Extraction

Purity : 99%

Volume : 25 kg

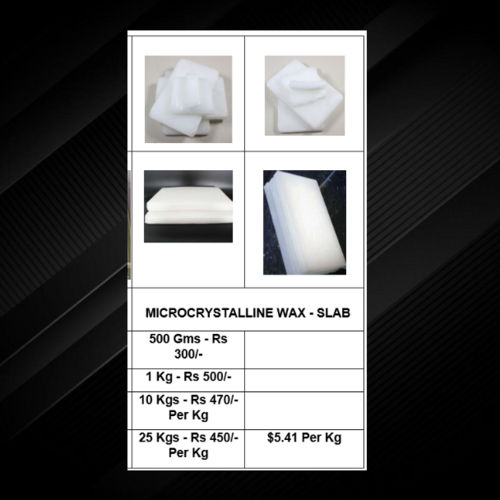

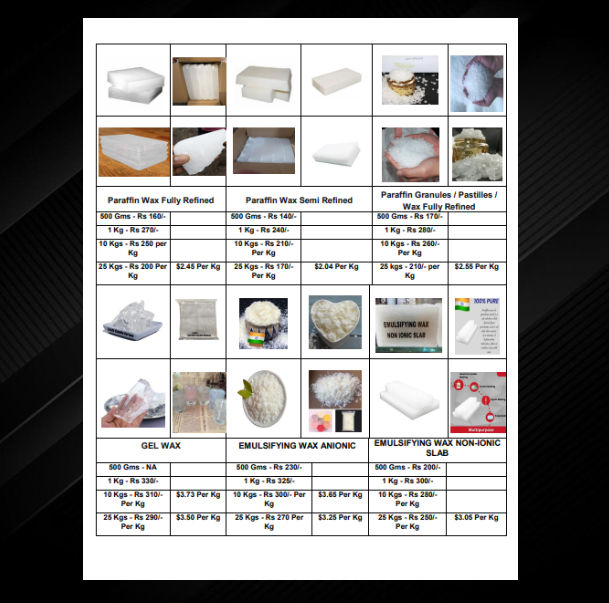

MICROCRYSTALLINE WAX - SLAB

Price 500 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Feature : Other, High plasticity; flexible; high melting point

Extraction Type : other, Refined extraction

Purity : 98% 100%

Volume : 25 Kg (per slab)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry